más noticias

JSE-Egaz estrena la ‘Enekoneta’ con la que difundir que «los socialistas somos la única alternativa a más nacionalismo»

El Secretario General del PSE-EE y candidato a Lehendakari, Eneko Andueza, ha participado junto a las Juventudes Socialistas de Euskadi (JSE-Egaz) en la presentación en Bilbao de la “Enekoneta”, la furgoneta con la que Juventudes Socialistas participará en la campaña...

La nueva Comisión Ejecutiva obtiene el respaldo del 94% de los/as delegados/as

“Sigue siendo necesario enarbolar las banderas que han caracterizado la lucha histórica de las Juventudes Socialistas, como el derecho a una Educación de calidad, a una vivienda digna, la convivencia en libertad, la igualdad y la lucha contra la violencia de género”...

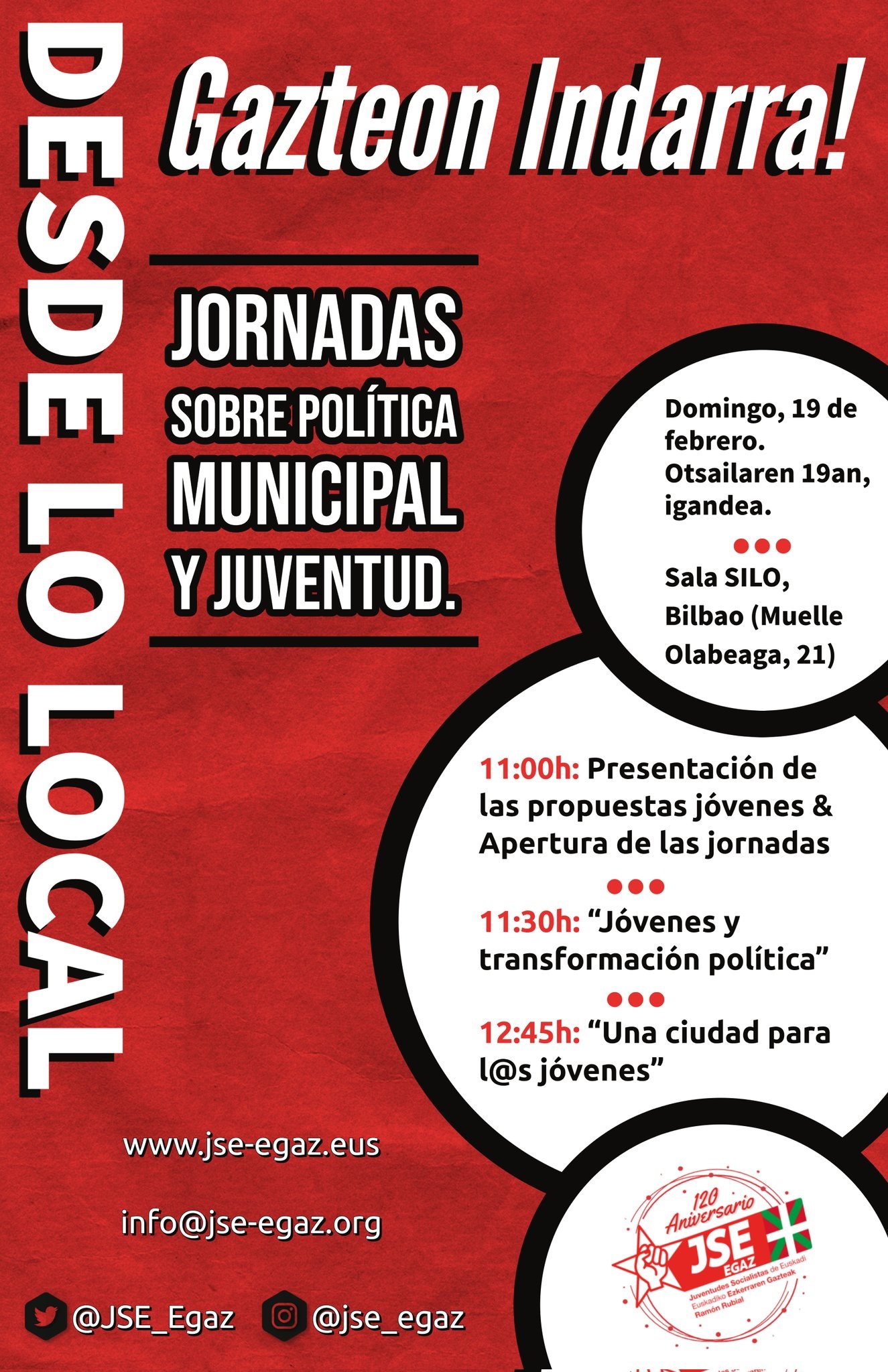

Juventudes Socialistas celebra en Bilbao su 120 aniversario con un Congreso Nacional y una exposición histórica

La organización celebrará en Bilbao, los días 30 de septiembre y 1 de octubre, su XI Congreso Nacional Ordinario para renovar su proyecto político y su dirección orgánica en Euskadi, que liderará Gabriel Arrúe, y desarrollará una exposición sobre su historia en el...

Homenaje a la II República en el Columbario de Orduña

Las Juventudes Socialistas de Euskadi llevaron a cabo el pasado 13 de abril en el Columbario de la Dignidad de Orduña un acto de homenaje a todas aquellas personas que dieron su vida por defender la II República. El acto, llevado a cabo la víspera del 14 de abril, día...

Edición especial de los Oroimen Hegoak con las Juventudes Laboristas Noruegas

El 22 de julio del año 2011 todos nos conmocionamos al conocer la noticia de los atentados de Utøya. Fue una masacre que sentimos como propia todos los progresistas de Europa y, especialmente, las Juventudes Socialistas de Euskadi, una organización que,...